Tyres- The basics Size’s

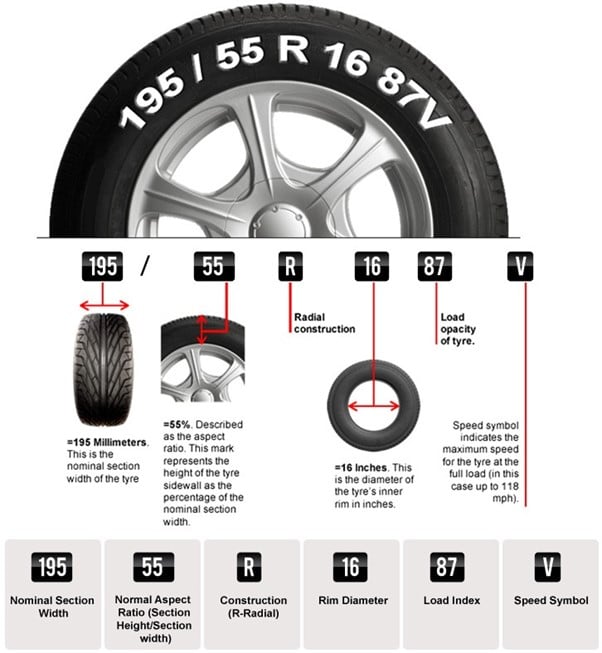

The most basic aspect of tyres often seems the most complicated and that is understanding the sizes. Below is a diagram to give you a break down on the tyre sizes and what each aspect relates to.

The pattern of the tyre indicates which axle position of the truck it can be fitted to and will often indicate speed and load rating.

Other markings you will find on a tyre’s sidewall can include;

|

M + S, which stands for “Mud and Snow” and indicates that the tyre is suitable for use in these winter conditions. However, M+S is a mark that can be added to a tyre without any regulation. So some customers don’t trust its legitimacy as much as the following; |

|

3PMSF or 3 peak mountain snowflake indicates the tyre meets required performance criteria in snow testing to be considered severe snow service rated. Originally used as a designation for winter tires, the 3PMSF symbol is now featured on some all-season and all-terrain tires with snow performance that meets the testing criteria. |

|

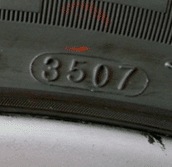

DOT Code- The date of tyre manufacture is typically seen as 4 digits together as demonstrated in this image. The first two digits are the week of manufacture, and the last two digits are the year. For example, if the last four digits of the DOT code are 3507, that means that the tire was manufactured during the 35th week of the year 2007. |

Tread depth

Current tread depth legislation requires that truck tyres must have a minimum of 1mm of tread in a continuous band throughout the central three-quarters of the tread width and over the whole circumference of the tyre. The same regulation applies to remoulded tyres. The penalty for driving with an illegal tyre is 2,500 and three penalty points per tyre.

When driving in wet weather, the tread pattern of the tyre helps to evacuate surface water from the road. As the tread begins to wear down, the tyre gradually loses the ability to evacuate all the water from the road surface, which increases stopping distances in the wet. The lower the tread depth, the greater the risk of aquaplaning, which is a loss of traction in wet circumstances.

Axle position’s

Different types of truck tyres are fitted across different axles on a truck and that is because each position has varying requirements.

|

Steer Arguably the most important on the truck. They influence handling, overall ride and offer a ribbed tread design that channels water away from the Tyre. All position tyres are mainly designed with the steer axle in mind. |

Drive A more aggressive pattern drive tyres are designed to maximise traction on varying road surfaces and weather conditions. The engine transfers the power to turn the drive tyres, so they need to be more robust to cope with that. |

Trailer Trailer patterns are created with a smoother pattern. They are often designed with resilience in mind with reinforced sidewalls and the capability to withstand the weight of heavy loads. These tyres are like steer patterns but able to hold the weight of heavy trailer loads. |

|

|

|

Different axle positions are indicated in the product description, each supplier will have a different descriptive pattern code relating to the position.